EverSkill provides precision CNC manufacturing from design to production, offering diverse machining capabilities for multiple industries. We deliver durable, high-quality, and cost-effective CNC parts.

EverSkill is dedicated to providing high-quality precision CNC component manufacturing solutions, covering the entire process from product design to mass production.

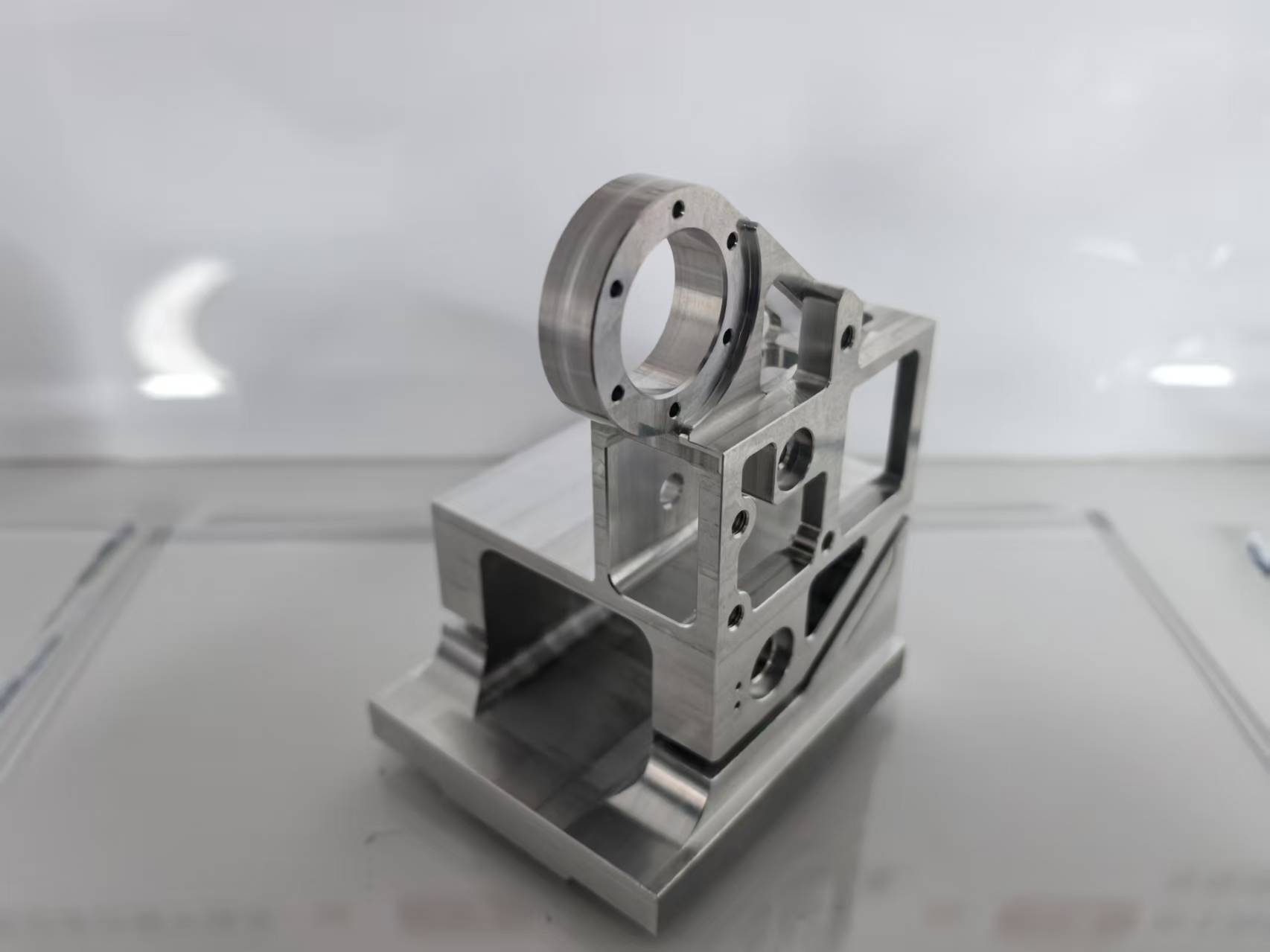

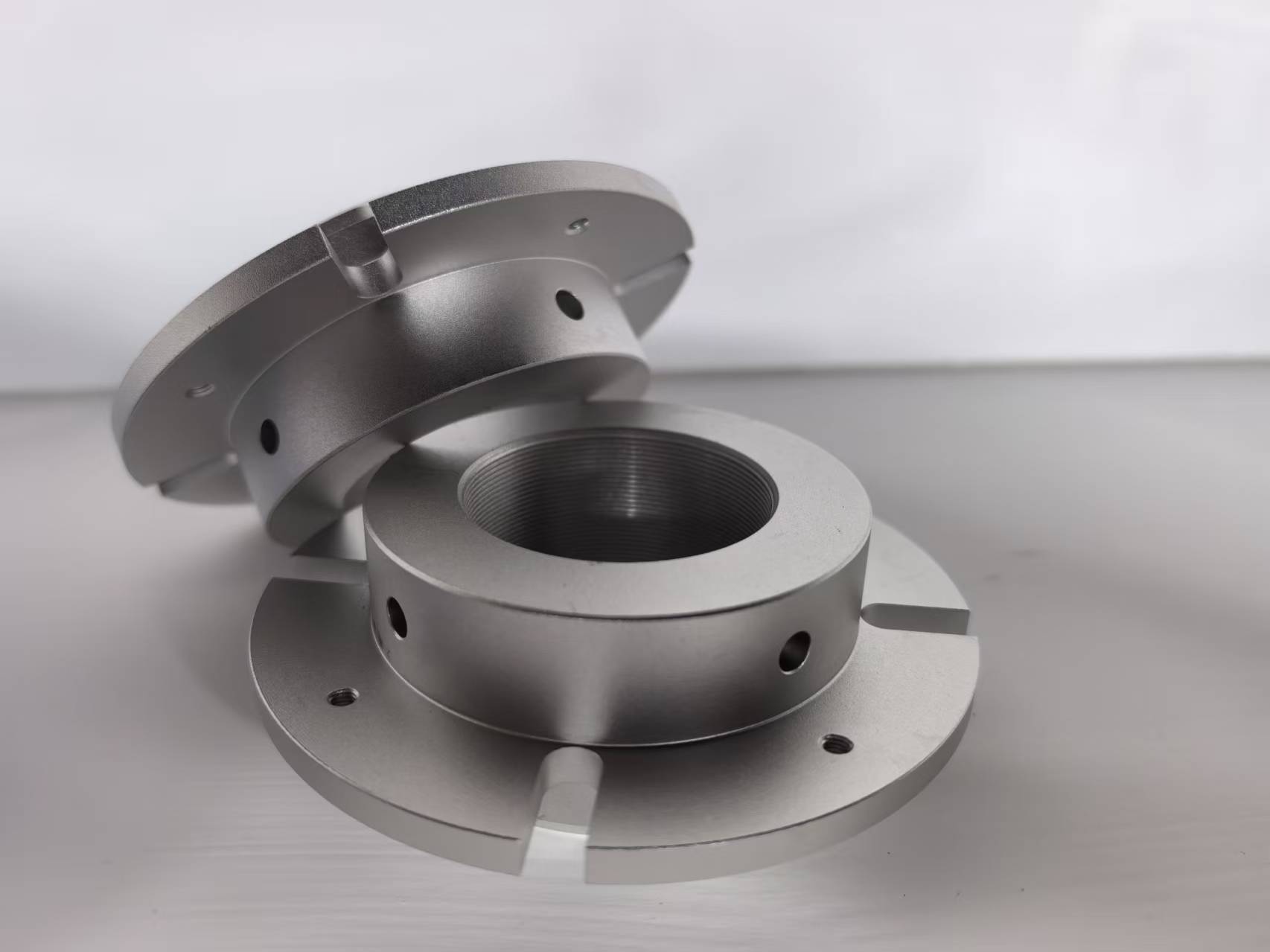

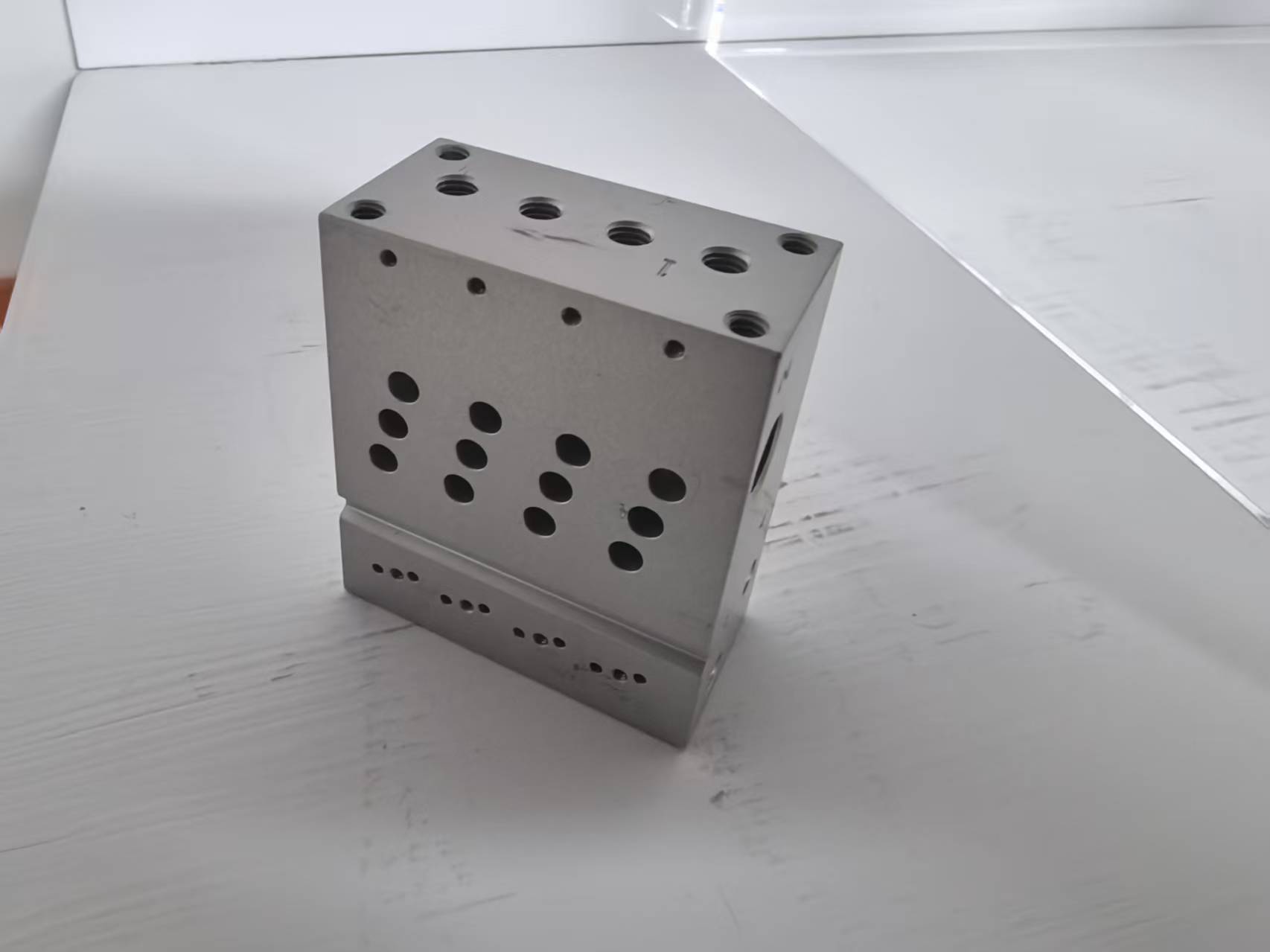

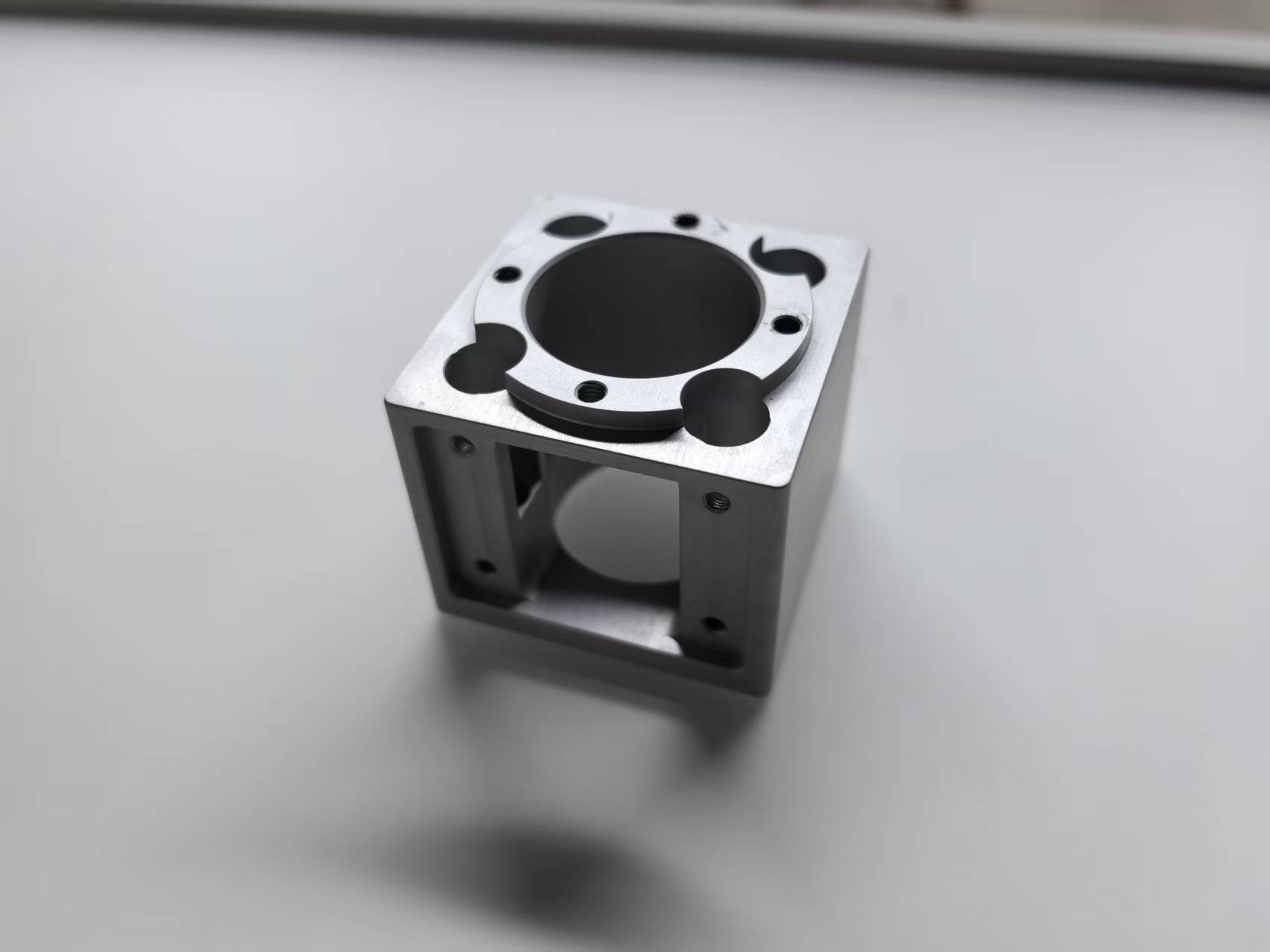

Our machining capabilities include CNC milling, CNC turning, grinding, turn-mill combined machining, wire-cutting, and spark-erosion machining, meeting the needs of various fields such as consumer electronics, medical devices, automotive parts, and industrial equipment.

The milling machine is operated by a digital control system, using a rotating milling cutter to perform milling operations on the workpiece.

The lathe is operated by a digital control system, using a lathe tool to perform turning operations on the rotating workpiece.

Using tools such as grinding wheels to perform grinding operations on the surface of parts, achieving high precision and high surface roughness of the workpiece.

An advanced machining technology that integrates turning and milling functions in a single machine tool.

Using custom-shaped electrodes made of copper/graphite, the material is eroded by electrical discharge to replicate the shape of the electrode, capable of machining complex three-dimensional cavities or blind holes.

Using a continuously moving metal wire (molybdenum or copper wire, with a diameter of 0.03--0.35mm) as the electrode, the workpiece is cut along a numerically controlled path.

Engineered components for demanding applications

We produce high-precision custom molded parts in plastic, silicone, and rubber. With advanced molding technologies, modern equipment, and experienced production teams.

Whether you need 5 prototypes or 50,000 units, our production lines adapt to your needs without compromising quality.

From early-stage design support to final production, we integrate every step to shorten lead times and reduce costs.

Our engineers work closely with clients, understanding both technical requirements and market realities to find the best solution.

Quality is not inspected at the end — it’s built into every process. Our teams follow a “right-first-time” principle.

We aim to grow together with our clients, providing insights and improvements that go beyond the original brief.

Connect with our engineering team to discuss your specific manufacturing requirements and explore innovative solutions.

Expert perspectives on industrial innovation and technology

EverSkill provides end-to-end manufacturing support through a professional engineering and production team. Our business scope includes project evaluation, engineering support, prototyping, quality coordination, and mass-production management.

We work closely with customers to optimize design, materials, and processes, ensuring stable quality, cost efficiency, and on-time delivery from development to full-scale production.

Direct communication drives innovation. Reach out and transform your manufacturing vision into reality.